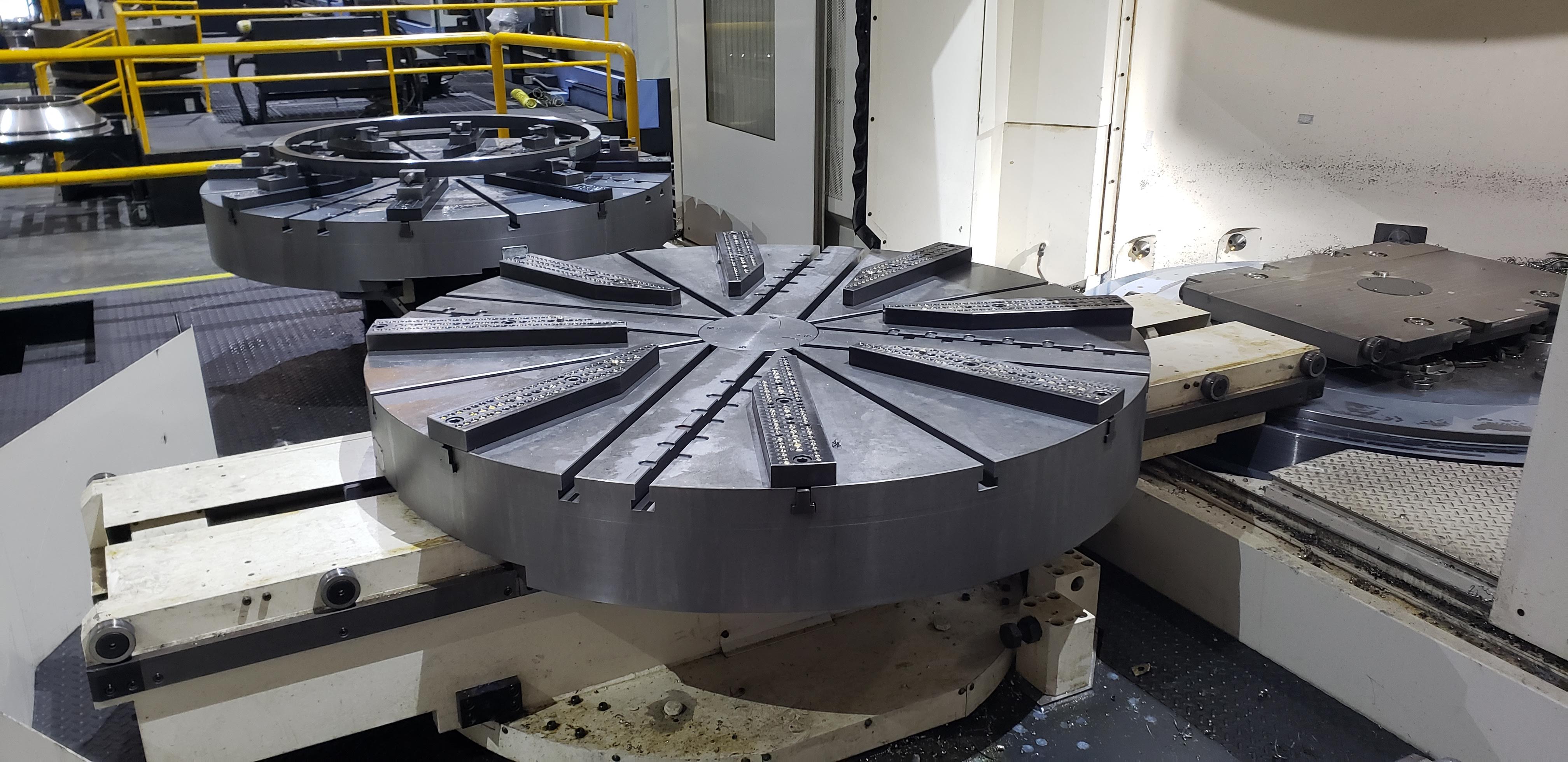

"We wanted Heavy duty machining without losing its capability and accuracy."

FRISA is one of the world´s leading forged steel manufacturer; We want to be the best option for each of our customers, offering high-value forging solutions; for the Aerospace industry, we´ve been providing seamless rolled rings in nickel and titanium alloys for components for aero engines.

We´ve been working with Shibaura Machine Company as one of our preferred machine-tool manufacturer for the last 10 years.

What the FRISA Aerospace Manufacturing Engineering Manager says

"The biggest challenge we have is to improve productivity and quality stability for our rough machining business. We wanted a machine that was proven to be reliable, that was good enough to perform heavy duty machining without losing its capability to be very accurate for high precision parts, and for that purpose, the Shibaura TUD model for vertical turning was a perfect fit for us."

Alejandro Montemayor

Manufacturing Engineering Manager

"The biggest challenge we have is to improve productivity and quality stability for our rough machining business. The Shibaura TUD model for vertical turning was a perfect fit for us."

Related Testimonials View All

There are various manufacturers in the market. We purchased Shibaura Machine for dependability and accuracy.

"The majority of our work is in the machine tool and plastic injection industries. When we were purchasing a new machine, we were looking for a dependable and accurate machine. We considered various manufacturers in the market. We went to Japan to see the ...

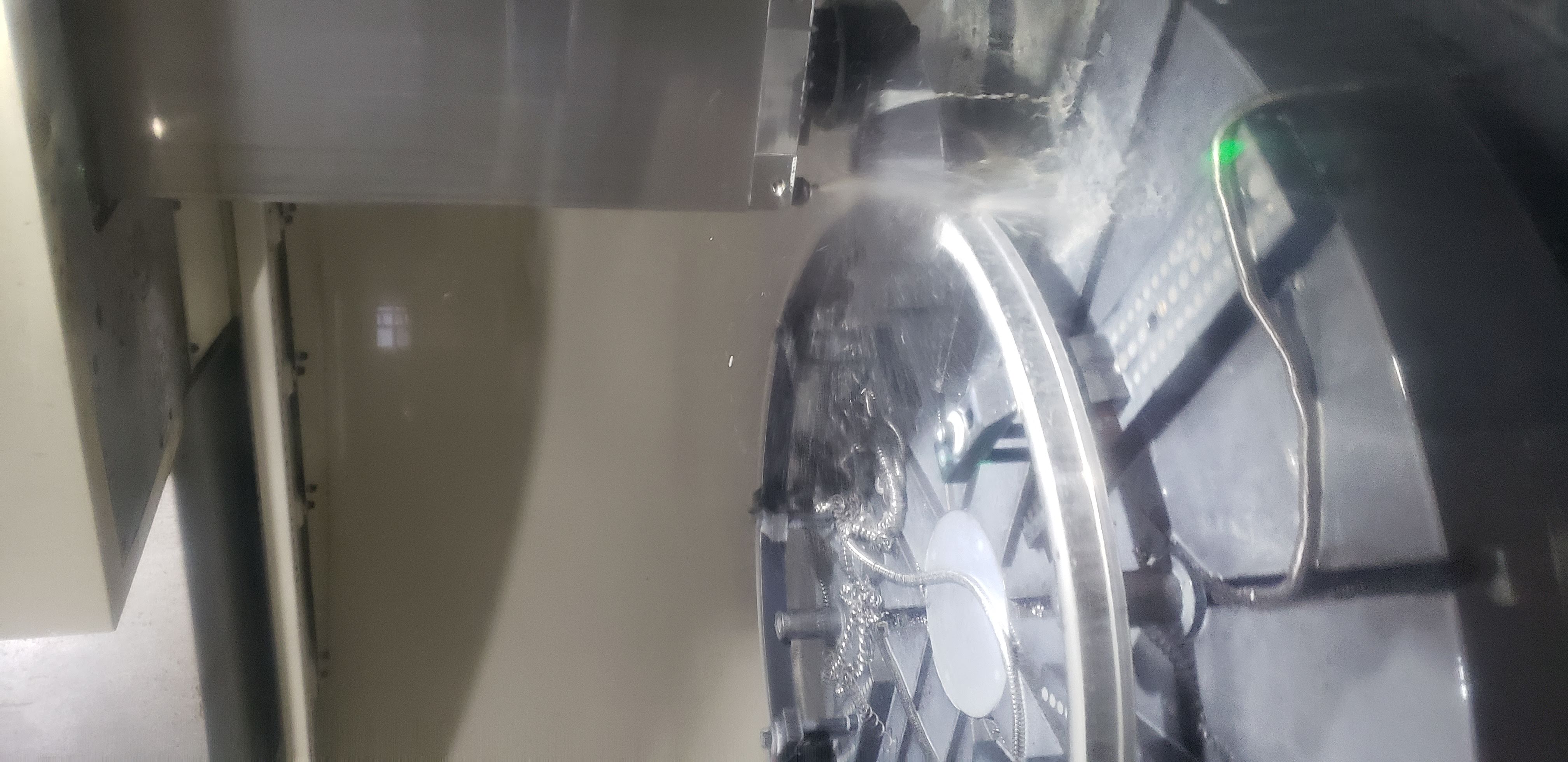

"A lot of our product line has small cycle times with different batch sizes, so with the Automatic Pallet changer we can reduce our downtime to a minimum, since we can perform all the setup on the outside without stopping the machine. The pallet can switch from one setup to another in less than 90 seconds, so that give us a competitive advantage compared to other machines without the APC.

We normally see 20-30% higher up-time in these machines since we can index and preset off-line with quick change tools without stopping, which is very critical for us since every 5 minutes we needed to stop to change inserts, and right now we can do it while the machine is running."

Alejandro Montemayor

Manufacturing Engineering Manager